When it comes to lighting solutions for industrial, commercial, and outdoor applications, one important category is Waterproof Fixture . These products are designed to withstand moisture, dust, and harsh environments while delivering reliable illumination. Many businesses source them from specialized suppliers, including a Led Waterproof Light Factory, where advanced designs ensure durable performance and safety. Whether you are considering a Waterproof Led Tube Fixture for a hallway or a Led Tube Water Proof Light Fixture for a factory floor, understanding the full potential of these products helps you make informed decisions.

Waterproof Fixture is more than just protective lights. It combines thoughtful engineering, resilient materials, and practical design to maintain performance under challenging conditions. Imagine preparing a meal in a steamy kitchen, working in a damp warehouse, or walking through a rain-soaked garden path. In each scenario, a sealed lighting unit provides dependable illumination while minimizing risk. Cige, focuses on producing solutions that are both durable and energy-efficient, blending functionality with aesthetics.

By exploring how these products are constructed, how they operate, and where they can be applied, you can better understand why moisture-proof fixtures are increasingly essential in both daily life and industrial operations.

Content

A moisture-proof fixture is engineered to resist water, dust, and environmental stressors. Unlike conventional indoor lights, which may fail when exposed to steam, rain, or humidity, these sealed units are built to remain functional under such conditions. The difference lies not only in the outer shell but also in the combination of materials, sealing methods, and internal engineering.

Key design elements include:

Sealed Housing: Typically made of polycarbonate or aluminum, housings offer strength, impact resistance, and protection against corrosion.

Gaskets and Seals: Rubber or silicone gaskets prevent moisture from entering sensitive areas, especially around joints and wire entry points.

LED Modules: Energy-efficient LEDs are often coated or embedded in protective layers to prevent short circuits or performance loss.

Secure Fasteners: Stainless steel screws and clips ensure the casing remains tightly sealed over time, even under vibration or minor impacts.

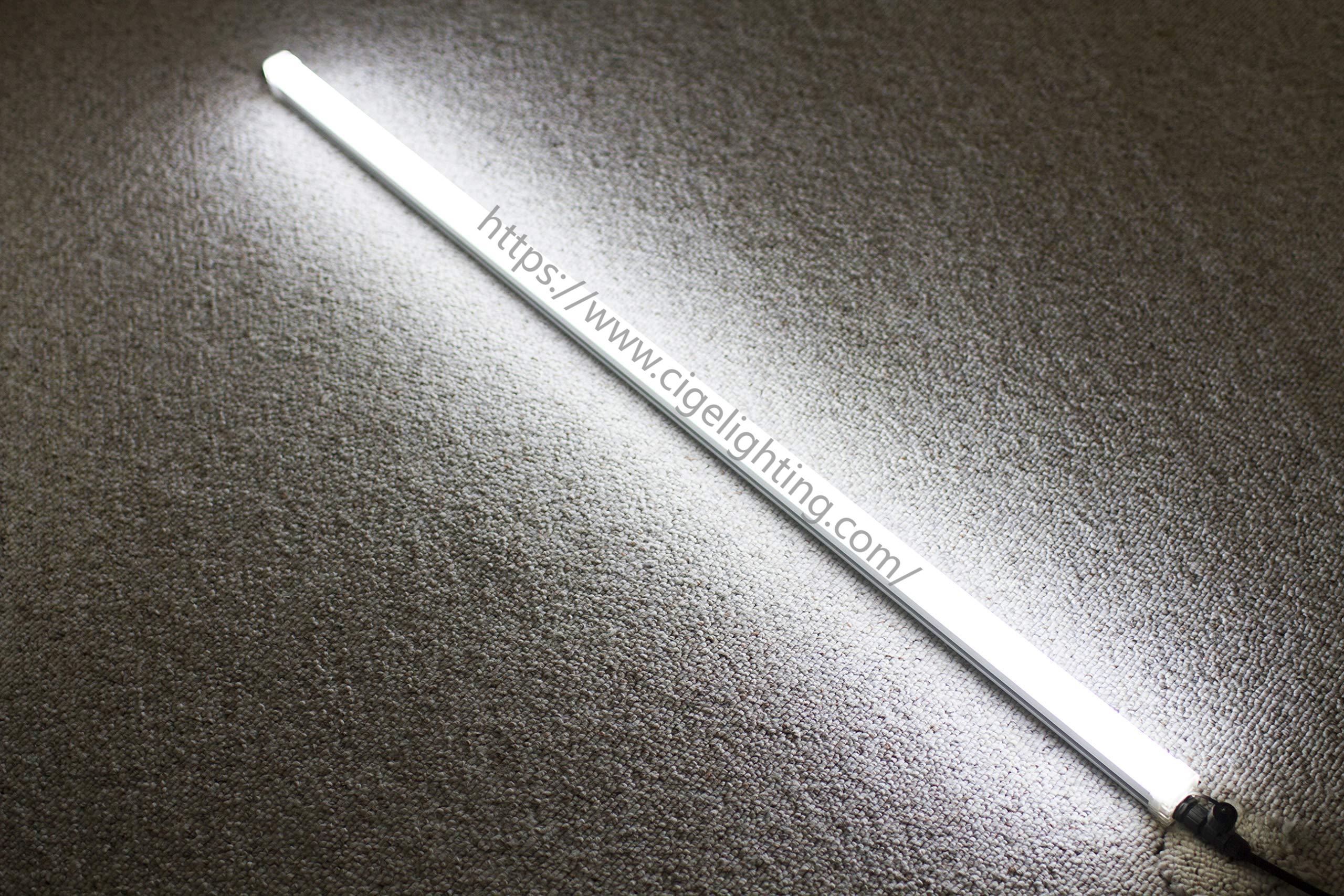

A Waterproof Led Tube Fixture is a practical example of applying water resistance to common lighting formats. Unlike regular fluorescent tubes, these fixtures feature end caps and tightly sealed housings that prevent moisture from infiltrating the light source. Similarly, a Led Tube Water Proof Light Fixture may look simple externally, but it incorporates engineering that anticipates condensation, humidity, and temperature fluctuations. Proper material selection, assembly, and testing are all critical to long-lasting performance.

Even mild humidity and temperature changes can damage conventional fixtures over time. Sealed lighting units prevent corrosion, electrical faults, and premature failure, providing reliable illumination in various settings.

These fixtures operate by keeping water and humidity away from sensitive electrical components. The engineering principles behind their operation are straightforward yet effective:

Sealing Techniques: Silicone or rubber gaskets around openings, joints, and connectors act as barriers against water intrusion. These seals are designed to maintain flexibility even under temperature changes.

Housing Materials: Polycarbonate covers and aluminum bodies offer both impact resistance and heat dissipation. Aluminum housings also help manage the heat generated by LED modules, which enhances longevity.

Drainage or Pressure Balancing: Some designs incorporate vents or small channels that allow minor condensation to escape while maintaining the overall integrity of the fixture.

In practical terms, this means the fixture can withstand direct splashes, humidity, steam, and even rain without losing performance or safety. A kitchen light, for instance, will maintain consistent illumination despite high humidity from boiling water. Outdoor wall lights remain functional during heavy showers, while factory lights resist dust, splashes, and accidental knocks.

LED technology complements these designs perfectly. LEDs produce less heat than traditional bulbs, reducing thermal stress on the seals and housing. When combined with durable materials and protective engineering, the fixture maintains its moisture-proof capabilities over extended periods.

Applications of Waterproof Lighting

Sealed lighting units have a wide range of applications. Below is a table summarizing common use cases and advantages:

| Application Area | Typical Fixture Type | Key Advantages |

|---|---|---|

| Residential Bathrooms & Kitchens | Compact tube lights, panels | Handles humidity, easy to clean, maintains consistent illumination |

| Outdoor Spaces | Floodlights, wall-mounted tubes | Resistant to rain, wind, and dust, enhances safety and aesthetics |

| Industrial Facilities | Tri-proof lights, tube fixtures | Withstands dust, steam, and impact, reduces maintenance and downtime |

| Public Infrastructure | Tunnels, parking lots, walkways | Long-lasting, improves visibility, durable under harsh conditions |

| Recreational Areas | Poolside and garden lights | Water-resistant, aesthetic design, energy-efficient and reliable |

Residential Use: Bathrooms and kitchens frequently encounter water and steam. A moisture-proof fixture in a bathroom prevents electrical issues caused by steam while keeping the area brightly lit. Outdoor residential areas such as patios, driveways, and gardens benefit from fixtures that can withstand rain or morning dew.

Commercial and Public Spaces: Parking garages, tunnels, and pedestrian walkways require dependable lighting for safety. Sealed lighting units reduce maintenance costs and minimize the risk of accidents caused by sudden light failure. These fixtures are also designed to endure dust and minor physical impacts.

Industrial Applications: Factories, warehouses, and food processing plants often experience moisture, dust, and high humidity. Tri-proof lights or Led Tube Water Proof Light Fixtures ensure continuous operation while lowering the likelihood of electrical hazards and production delays.

Recreational and Outdoor Spaces: Swimming pools, fountains, and landscaped gardens need lights that resist water exposure without compromising design or performance. Modern moisture-proof fixtures provide both reliable illumination and aesthetic appeal.

Choosing the Right Water-proof Fixture

Selecting the right fixture requires consideration of the environment, purpose, and performance requirements.

1. Location: Indoor damp areas may require compact tube lights or panels. Outdoor installations demand sturdier housings and higher impact resistance.

2. Brightness and Color Temperature: Higher lumens are suitable for industrial or commercial spaces, while residential areas may benefit from moderate brightness. Color temperature selection—warm, neutral, or cool white—affects comfort and visual clarity.

3. Materials and Durability: Aluminum housings offer strength and heat dissipation. Polycarbonate provides lightweight impact resistance. Seals should maintain flexibility across temperature changes.

4. Fixture Type: A Waterproof Led Tube Fixture works well for corridors and office spaces. A Led Tube Water Proof Light Fixture is often preferred for larger or high-demand areas, such as factories or warehouses.

Evaluating these factors ensures reliable, long-lasting performance and reduces replacement, maintenance, and energy costs. Proper selection also helps maintain safety standards in moisture-prone environments.

Even the most durable waterproof fixtures benefit from periodic maintenance. Some essential tips include:

Exterior Cleaning: Wipe housings with a soft, damp cloth to remove dust, dirt, or residue. Avoid abrasive or chemical cleaners that may damage seals.

Seal Inspection: Check gaskets, rubber components, and connection points for wear or loss of flexibility. Replacing worn seals can prevent water ingress.

Fastener Check: Ensure screws and mounting clips remain tight to preserve the integrity of the seal.

Driver and LED Monitoring: If brightness diminishes, replacing the driver can restore performance without discarding the entire fixture.

Routine care helps extend the lifespan of moisture-proof lighting units while maintaining safety and efficiency.

Technology Trends in Water-proof Led Tube Fixture

The lighting industry continues to innovate, and moisture-resistant fixtures are evolving alongside it:

Smart Integration: Motion sensors, dimming, and remote control systems improve adaptability for residential, commercial, and industrial settings.

Eco-Friendly Materials: Recyclable housings and energy-efficient LEDs support sustainable lighting solutions.

Solar-Powered Options: Off-grid outdoor lighting benefits from solar energy, reducing power consumption.

Sleeker Designs: Modern designs combine aesthetics with robustness, proving that durability does not require bulky or unattractive housings.

These developments ensure moisture-proof fixtures remain relevant, functional, and appealing to a wide range of users.

Reliable lighting influences safety, comfort, and efficiency. Dark parking garages, damp basements, or humid warehouses can be hazardous. Moisture-proof fixtures reduce risks, prevent accidents, and provide consistent illumination for both work and leisure activities.

In recreational spaces such as gardens or pool areas, these fixtures maintain ambiance while withstanding rain or splashes. Their energy efficiency, combined with long-lasting LED technology, ensures cost-effective and environmentally friendly operation.

By integrating durability, energy savings, and thoughtful design, sealed lighting units address both practical and aesthetic demands, making them a versatile solution for homes, businesses, and public spaces.

Cige, as a Led Waterproof Light Factory, specializes in producing durable, energy-efficient, and versatile moisture-resistant lighting units. Each product undergoes rigorous testing to ensure reliability in various conditions, from industrial warehouses to outdoor recreational areas. By sourcing from a specialized factory, clients gain access to high-quality, tailored solutions, including led tube water proof light fixtures, with consistent performance and compliance with safety standards.

Their commitment to innovation, material selection, and thoughtful design ensures long-term satisfaction, reduced maintenance, and energy-efficient lighting for every environment.

From residential bathrooms to industrial warehouses, public spaces, and outdoor recreational areas, moisture-proof lighting has become a cornerstone of safe, reliable illumination. Whether installing a Waterproof Led Tube Fixture indoors or a Led Tube Water Proof Light Fixture in a factory, choosing well-designed, sealed lighting units guarantees dependable performance, safety, and energy efficiency. Cige continues to provide practical, durable, and innovative solutions for diverse lighting needs.

It is focused on the overall solution of dry bulk material port transfer system,

research and development, manufacturing, and service.

+ 86-158 6784 4739

garrick@cigelighting.com

+ 86-574 5896 6613

No. 332, Yizidi, Zhoutang west village. Zonghan street, Cixi, Ningbo, Zhejiang Province, China

Copyright © Ningbo Cige Photoelectric Technology Co., Ltd. All Rights Reserved. Triproof Light Manufacturer